Manual paper cutters are essential tools for precisely cutting paper in offices, schools, and print shops. They offer a cost-effective, efficient way to trim paper, ensuring accuracy and safety.

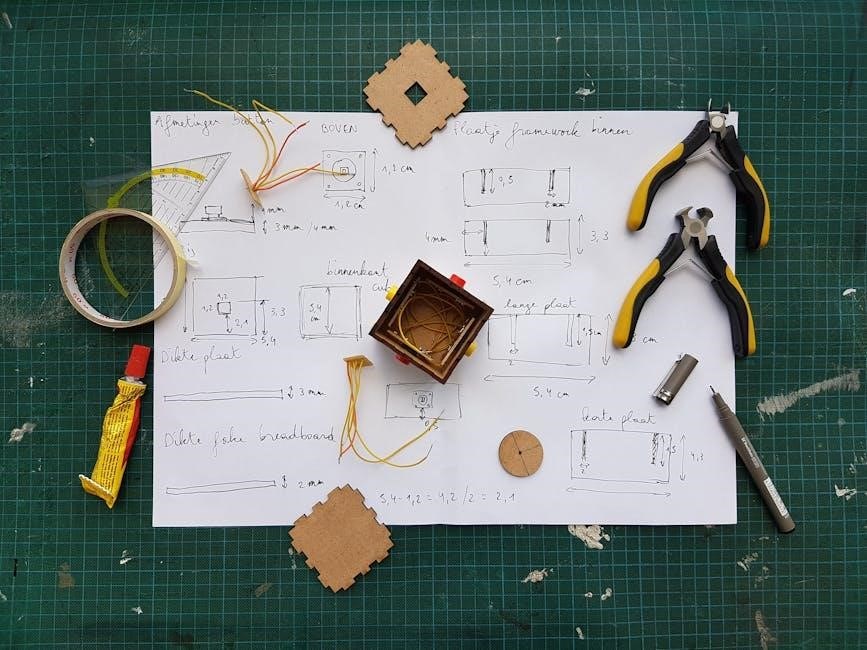

Components of a Manual Paper Cutter

A manual paper cutter typically consists of a sturdy base, a sharp blade, a handle or lever, an alignment guide, and a clamp or locking mechanism to ensure precise and safe cutting operations.

2.1. Base

The base of a manual paper cutter is its foundation, providing stability and support during cutting operations. Typically made of durable materials like wood or metal, it ensures a firm, flat surface for placing paper. The base often features an alignment guide to help users position the paper accurately, which is crucial for achieving straight cuts. Some models include a clamp or locking mechanism on the base to secure the paper in place, minimizing movement and enhancing safety. The base’s design plays a significant role in the cutter’s overall performance, as it directly impacts precision and ease of use. A sturdy base is essential for handling various paper sizes and thicknesses, making it a critical component for both professional and casual use. Regular maintenance, such as cleaning and ensuring the base remains level, is recommended to maintain optimal functionality. The base’s durability and stability are key factors in the longevity and effectiveness of the paper cutter.

2.2. Blade

The blade is a critical component of a manual paper cutter, responsible for making precise cuts through paper. It is typically made from high-carbon steel or other durable materials to ensure sharpness and longevity. The blade’s edge is carefully designed to slice through stacks of paper smoothly, minimizing the risk of tearing or uneven cuts. Some blades feature a curved or angled design to enhance cutting efficiency and control. Regular maintenance, such as cleaning and sharpening, is essential to maintain the blade’s performance. Over time, the blade may dull, requiring replacement or professional sharpening to restore its cutting ability. Safety is a key consideration, as the blade can be extremely sharp, so proper handling and storage are crucial. The blade’s quality and design directly impact the cutter’s overall performance, making it a vital part of the tool’s functionality and effectiveness for various cutting tasks.

2.3. Handle or Lever

The handle or lever is a vital component of a manual paper cutter, designed to provide the necessary force and control to operate the blade. Typically located on one side of the cutter, the lever is ergonomically designed for comfort and ease of use. It is usually made from durable materials such as metal or high-strength plastic, ensuring longevity and reliability. When pressed or pulled, the lever transfers the applied force to the blade, enabling precise and clean cuts through the paper stack. Some models feature a long, extended lever to maximize cutting power, while others offer a more compact design for convenience. The handle’s grip is often textured or cushioned to prevent slipping, enhancing safety and control during operation. The lever’s smooth motion and responsive mechanism are essential for achieving consistent results, making it a key element in the overall functionality of the paper cutter.

2.4. Alignment Guide

The alignment guide is a crucial feature of manual paper cutters, designed to ensure precise and accurate cuts. It typically consists of a ruler, grid, or marked edge along the base of the cutter, allowing users to position the paper correctly before cutting. This guide helps in achieving straight cuts and maintaining consistency, especially when trimming multiple sheets at once. Some models feature adjustable alignment guides, enabling users to customize the cutting edge based on specific requirements. The guide also helps in preventing crooked cuts and waste, making the cutting process more efficient. For users working with large or irregularly shaped paper, some cutters include extendable or detachable alignment guides to accommodate different sizes. The alignment guide is essential for both professional and DIY projects, ensuring that the final result meets the desired specifications. Its presence enhances the overall functionality of the paper cutter, making it a key component for achieving professional-grade results.

2.5. Clamp or Locking Mechanism

The clamp or locking mechanism in a manual paper cutter is a vital component designed to hold the paper securely in place during the cutting process. This feature ensures that the paper remains steady, preventing any movement that could lead to uneven cuts or accidents. The clamp can be either manual, requiring the user to press or tighten it, or automatic, engaging automatically when the cutting process begins. Automatic clamps are particularly beneficial for heavy-duty use, offering convenience and efficiency.

In guillotine cutters, a robust clamp is essential for handling heavy-duty cutting tasks, ensuring smooth blade operation and maintaining machine integrity. The clamp is typically made from durable materials like metal or high-quality plastic to withstand regular use without wear. Adjustability is a key feature, allowing the clamp to accommodate various paper thicknesses and materials, such as cardstock or thin plastics, enhancing the cutter’s versatility.

Safety is further enhanced by features that prevent blade movement unless the clamp is properly engaged. This ensures the cutter cannot operate until the paper is securely held, adding an extra safety layer. The clamp also contributes to cutting efficiency by enabling quicker and more confident cuts, crucial in professional settings. Regular maintenance, such as cleaning to remove debris, is necessary to sustain optimal performance. Thus, the clamp significantly improves the precision, safety, and efficiency of the cutting process.

Types of Manual Paper Cutters

Manual paper cutters include guillotine, rotary, stack, and craft cutters, each designed for specific tasks, offering precision and versatility for various cutting needs in offices, homes, and craft projects.

3.1. Guillotine Cutters

Guillotine cutters are among the most common types of manual paper cutters, known for their simplicity and effectiveness. They feature a sharp blade that descends vertically to cut through paper stacks. These cutters are ideal for precise, straight cuts and are widely used in offices, schools, and print shops. The design typically includes a lever or handle that the user pulls down to operate the blade, ensuring control and accuracy. Guillotine cutters are available in various sizes, ranging from small, desktop models for personal use to larger, heavy-duty versions capable of cutting through hundreds of sheets at once. They are particularly popular for their durability and ease of maintenance. For optimal performance, users should regularly sharpen the blade and ensure the cutter is placed on a stable surface. Guillotine cutters are a reliable choice for anyone needing to cut paper efficiently and safely.

3.2. Rotary Paper Trimmers

Rotary paper trimmers are a popular choice for precise and smooth paper cutting. Unlike guillotine cutters, they use a rotating circular blade that glides along a fixed track, ensuring clean, straight cuts. These trimmers are ideal for applications requiring high accuracy, such as scrapbooking, photo trimming, and crafting. They are often preferred for their ease of use and ability to cut through multiple sheets of paper with minimal effort. Rotary trimmers are lightweight and portable, making them a great option for home, office, or classroom use. Safety features like protective guards and secure locking mechanisms are common, preventing accidental cuts. Maintenance is straightforward, as the blade can be replaced or sharpened when needed. Rotary paper trimmers are versatile tools that cater to both casual users and professionals, offering a reliable solution for precise paper cutting tasks.

3.3. Stack Cutters

Stack cutters are designed to efficiently cut through multiple sheets of paper at once, making them ideal for high-volume tasks. These cutters typically feature a sturdy base, a sharp blade, and a manual lever or handle to apply pressure. They are commonly used in offices, schools, and print shops for trimming large stacks of documents, photos, or cards. Stack cutters are known for their precision and ability to maintain straight cuts, even when handling thick piles of paper. Safety features, such as protective guards and secure locking mechanisms, are often included to prevent accidents. Maintenance is minimal, with periodic blade sharpening or replacement required to maintain optimal performance. Stack cutters are a reliable and durable choice for users who need to cut multiple sheets quickly and accurately, offering a practical solution for both small-scale and industrial applications.

3.4. Craft and Specialty Cutters

Craft and specialty cutters are designed for precise, intricate cutting tasks, making them ideal for artistic projects and detailed work. These cutters often feature adjustable blades, allowing users to achieve unique cuts, such as curved or angled edges. They are popular among crafters, scrapbookers, and artists who need to create custom shapes or designs. Some models include specialized features like scoring tools or interchangeable blades for versatility. Craft cutters are typically smaller and more portable than standard cutters, making them convenient for desktop use. They are also often used in schools for educational projects and by hobbyists for tasks like card making or origami. Despite their smaller size, these cutters maintain high precision, ensuring clean, accurate cuts. Many models come with safety features, such as protective guards, to prevent accidents. Craft and specialty cutters are essential tools for anyone requiring detailed, creative paper cutting solutions.

Buying Guide for Manual Paper Cutters

Consider size, precision, and safety when selecting a manual paper cutter. Choose models with adjustable guides and durable blades for accurate cuts. Budget options vary, from basic to heavy-duty models for larger capacities.

4.1. Size and Cutting Capacity

When selecting a manual paper cutter, consider the size and cutting capacity to meet your needs. Cutters vary in size, from small desktop models for A4 sheets to larger A3 models for bigger projects. Heavy-duty cutters can handle up to 50 sheets at once, while basic models typically cut 10-15 sheets. Blade length determines the maximum cutting length, so choose one that accommodates your paper size. For precise cuts, look for models with adjustable guides to align paper accurately. Consider the application—small cutters are ideal for home use, while larger ones suit offices or print shops. Ensure the cutter fits your workspace and can handle the thickness of materials you work with, such as cardstock or photo paper. Selecting the right size ensures efficiency and avoids wasting time on multiple cuts.

4.2. Precision and Accuracy

Precision and accuracy are critical factors when choosing a manual paper cutter. A high-quality blade ensures clean, straight cuts, while an alignment guide helps position paper correctly for consistent results. Look for models with a sturdy clamp or locking mechanism to keep the paper in place during cutting, minimizing shifts that cause uneven edges. Adjustable blades allow for angled or specialty cuts, adding versatility for craft projects or specific trimming needs. Ergonomic handles and balanced designs improve control, reducing fatigue and ensuring accurate cuts. For professional-grade results, opt for cutters with laser-guided alignment or precision-engineered blades. Regular maintenance, such as sharpening the blade, is essential to maintain cutting accuracy over time. By prioritizing precision, users can achieve professional-quality cuts whether for office tasks, crafting, or industrial applications.

4.3. Safety Features

Safety features are paramount when selecting a manual paper cutter to prevent accidents and ensure safe operation. Many models include a safety latch or blade lock to secure the blade when not in use, reducing the risk of unintended cuts. A protective guard or cover over the blade further enhances safety by preventing accidental contact. Additionally, some cutters feature an emergency stop mechanism to halt the blade mid-cut if needed. It’s essential to choose a cutter with a stable, heavy-duty base to prevent tipping and ensure consistent performance. Always follow operating instructions, such as keeping hands away from the blade and avoiding loose clothing that could get caught. Placing the cutter on a flat, stable surface and supervising children while in use are also crucial precautions. Prioritizing safety features ensures a secure and reliable cutting experience for both professionals and casual users.

4.4. Budget Considerations

Budget considerations play a significant role in selecting the right manual paper cutter, as options vary widely in price and functionality. Basic models designed for light use, such as cutting a few sheets at a time, are often affordable and cost under $50. These entry-level cutters are ideal for small offices or personal use. Mid-range models, offering higher cutting capacities and improved durability, typically fall between $50 and $150. They are suitable for moderate use in professional settings. Heavy-duty cutters, capable of cutting large stacks or thick materials, can range from $150 to several hundred dollars. These are best for industrial or high-volume applications. It’s important to balance your budget with your specific needs, as over-investing in unnecessary features or under-investing in a cutter that lacks required capabilities can be costly in the long run. Always compare prices and features to find the best value for your money.

Safety Precautions and Best Practices

Safety is paramount when using a manual paper cutter to avoid accidents and ensure efficient operation. Always keep your hands and fingers away from the blade during use, and never reach underneath the cutter while it is in motion. Ensure the cutter is placed on a stable, flat surface to prevent it from tipping over. Avoid distractions and maintain focus while cutting to minimize the risk of injury. Wear protective gear, such as gloves, if handling large or sharp materials. Follow the manufacturer’s instructions for operating and maintaining the cutter, and never bypass safety features like blade guards or clamps. Regularly inspect the blade for wear and tear, as a dull blade can lead to uneven cuts and increased risk of accidents. Store the cutter out of reach of children and in a secure location when not in use. By adhering to these guidelines, you can ensure a safe and effective cutting experience.

How to Use a Manual Paper Cutter

To use a manual paper cutter effectively, start by placing it on a stable surface. Align the paper using the guide, ensuring it is straight and even. Secure the paper with the clamp or locking mechanism to prevent movement during the cut. Grasp the handle or lever firmly and apply steady, controlled pressure to lower the blade. Keep your hands and fingers clear of the blade’s path to avoid injury. After the cut, allow the blade to return to its resting position before removing the paper. Test the cutter with a lower quality paper first to ensure accuracy and safety. Regularly maintain the blade and other parts to ensure optimal performance. Always follow the manufacturer’s instructions for specific guidelines and safety precautions. Proper technique and attention to safety will yield precise cuts and prevent potential hazards.

Maintenance and Care Tips

Regular maintenance is crucial to ensure the optimal performance and longevity of a manual paper cutter. Start by cleaning the blade and base with a soft cloth to remove dust and debris. Lubricate the blade periodically to maintain sharpness and smooth operation. Inspect the blade for dullness or damage and replace it as needed. Store the cutter in a dry place to prevent rust and corrosion. Always test the cutter with a lower quality paper before regular use to ensure accuracy. Check the alignment guide and clamp mechanism for proper function and adjust if necessary. Avoid cutting materials other than paper, as this can damage the blade. Keep the cutter out of reach of children and ensure all safety features are intact. Refer to the user manual for specific maintenance instructions, as different models may have unique requirements. Proper care will extend the life of the cutter and ensure precise cuts every time.

Applications and Uses of Manual Paper Cutters

Manual paper cutters are versatile tools with a wide range of applications across various industries. They are commonly used in offices for trimming documents, business cards, and photos. Schools and educational institutions rely on them for arts and crafts projects, while print shops utilize them for precise cutting of large paper stacks. Craft enthusiasts employ manual cutters for scrapbooking, card making, and intricate paper designs. They are also ideal for cutting cardstock, foam, and lightweight materials. In industrial settings, heavy-duty models are used for cutting thick paper, cardboard, and plastic sheets. Additionally, manual paper cutters are popular among photographers for trimming photos to size. Their precision and ease of use make them essential for both professional and DIY projects. Whether for everyday office tasks or specialized crafting, manual paper cutters remain an indispensable tool for achieving clean, accurate cuts;

User Reviews and Ratings

Manual paper cutters have received overwhelmingly positive reviews from users across various industries. Many praise their durability, precision, and ease of use. Office professionals highlight their reliability for everyday tasks, while crafters appreciate their versatility for intricate cuts. Safety features, such as secure blades and stable bases, are frequently commended. Users also appreciate the cost-effectiveness of manual cutters compared to automatic models. Some reviewers mention that higher-end models offer superior cutting capacity and longevity. However, a few users note that blade replacement can be challenging, and some models may require frequent adjustments. Overall, manual paper cutters are highly rated for their performance, with many users recommending them for both professional and personal use; Their ability to deliver clean, accurate cuts consistently earns them top marks in user feedback.

Comparison with Other Cutting Tools

Manual paper cutters stand out among other cutting tools for their unique combination of affordability, precision, and ease of use. Unlike automatic paper cutters, manual models rely on physical effort, offering a cost-effective solution without compromising on performance. They are often compared to scissors, but manual cutters excel in cutting straight lines and handling multiple sheets simultaneously. Craft knives and rotary trimmers are alternatives, but manual cutters provide better control for precise cuts. Electric paper cutters, while faster, lack the portability and simplicity of manual models. Manual cutters are also quieter and require less maintenance compared to electric versions. For small to medium-sized tasks, they are often preferred over bulkier industrial cutters. Their durability and versatility make them a popular choice for both office and craft projects. Overall, manual paper cutters offer a practical balance between functionality and cost, making them a enduring choice for various applications.

Manual paper cutters remain an indispensable tool for precise and efficient paper cutting across various settings, from offices to craft projects. Their simplicity, affordability, and durability make them a preferred choice for many users. Unlike automatic or electric cutters, manual models offer a cost-effective solution without compromising on accuracy. They are easy to maintain, portable, and require no electricity, making them ideal for small-scale tasks. Safety features and adjustable guides ensure clean, straight cuts, while their versatility accommodates different paper sizes and thicknesses; Whether for professional or personal use, manual paper cutters provide reliable performance and long-lasting durability. With proper care and maintenance, they continue to be a practical and essential tool for anyone needing precise paper cutting capabilities. Their enduring popularity underscores their value in both traditional and modern applications.

Future Trends and Innovations

Manual paper cutters are evolving to meet modern demands, with advancements focused on improving efficiency, safety, and versatility. Future trends include the integration of ergonomic designs to reduce user fatigue and enhance precision. Innovations in blade technology, such as self-sharpening or diamond-coated blades, aim to extend durability and maintain cutting performance. Additionally, manufacturers are exploring eco-friendly materials and energy-efficient production methods to align with sustainability goals. Smart features, like adjustable digital guides or Bluetooth connectivity for pre-programmed cuts, may soon become standard in high-end models. The rise of 3D printing is also inspiring customizable paper cutter designs, allowing users to tailor tools to specific needs. As technology advances, manual paper cutters will continue to balance tradition with innovation, offering practical solutions for both professional and creative applications while staying competitive in a rapidly changing market.